Gathering machine data

More transparency in the production and data analysis for a well-aimed production plan. This is what you can reach through our easy-configurable data collector.

A small computer with great performance

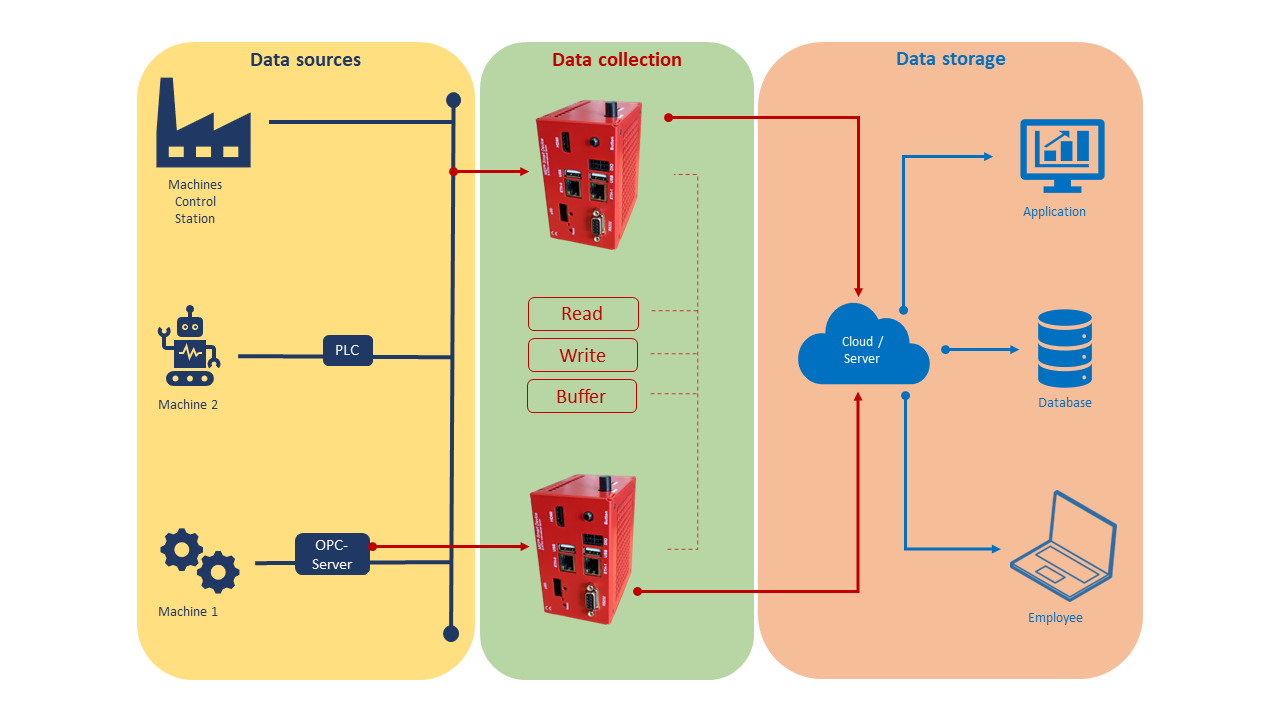

Our MEP®DataRecorder represents a complete solution for machine data collection! Data can be sent to applications and machines or directly to the cloud. This allows access to the collected data from different departments of the company, for example the IT department.

All information at a glance

With MEP®DataRecorder it is possible to record and collect data in a quick and easy way, from machine PLC, digital and analogue sensors, as well as from other type of sources. On this basis, the product allows to monitor all the important information, such as energy consumption, temperature, humidity and the number of pieces produced. Thus, the employee can detect variations or irregularities and consequently act before it results in defects or failures. Regular controls reduces failures rate, a higher efficiency of the machine reduces costs.

Short preview of the interface

Commonly asked questions to collecting machine data.

What are machine data?

Machine data is all data that is available on a machine and can be recorded. For example, this includes data such as temperature or rotational speed, but also availability and downtime.

What is machine data collection?.

Machine data collection ("MDC" for short) is the interface between the machines in a production facility and the IT system. The required machine data is collected and stored so that it can be used for subsequent evaluations.

What is machine data collected for?

Using the stored machine data, evaluations, live dashboards or key figures can be calculated and displayed. This allows processes to be optimised or problems to be detected at an early stage, which in turn ensures greater efficiency, time and cost savings.